My Spyder Caracas has some 350K miles on it.. It's my DD, and it was time at 300K to rebuild a motor..

When I decided to rebuild, I wanted a little more Zip.. I already had the MAF Mod ( Serial number 1! ).. and the next things to add were Cams and a Lightweight Flywheel..

The Cams were Crower Stage 1, and the Flywheel I purchased as New in Box from a Spyder member who decided to go 2ZZ ( Thanks Triz! )..

The Flywheel was a Light Weight Steel.. just what I wanted.. As aluminum kinda gives me the Kreeps..

I have about 40 K on this Flywheel.. and the Clutch had 120K when it went BACK in as used.. all checked out good.. my last Clutch had 175K miles and still looked good when I decided to take it out, I'd figure I toss this clutch back in.. with the new flywheel and Cams.. ( with the fresh rebuild of the Engine and trans..)

Last week on my way to work ( 175 Mile round trip ) my Clutch went from Fine to Fubar in one shift.. Lots of Noise, and would not disengage. I got to finish my drive to work, then back home again with out a clutch.. ( Must shift well or it's over )

I got the Clutch out today, and learned something..

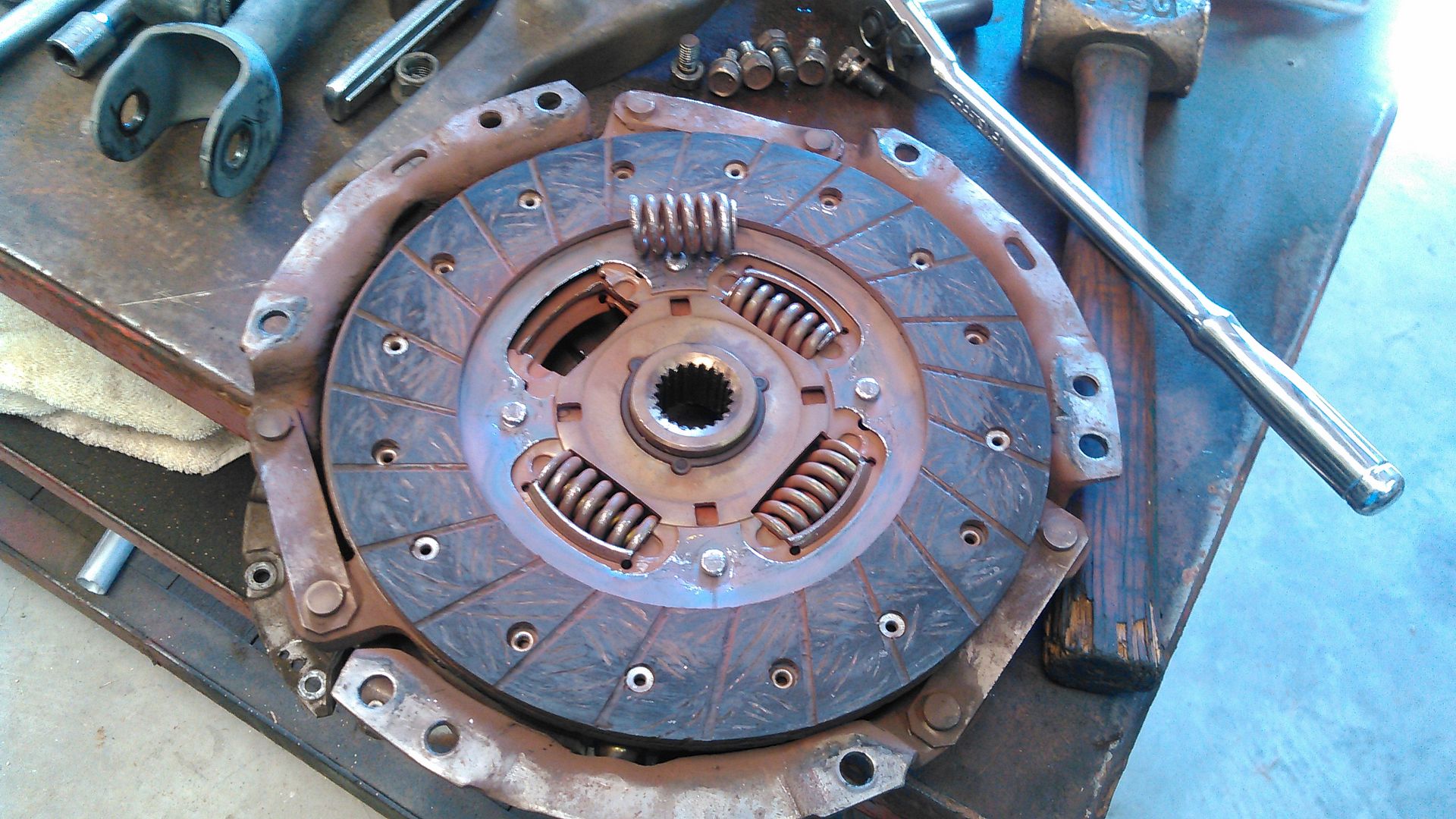

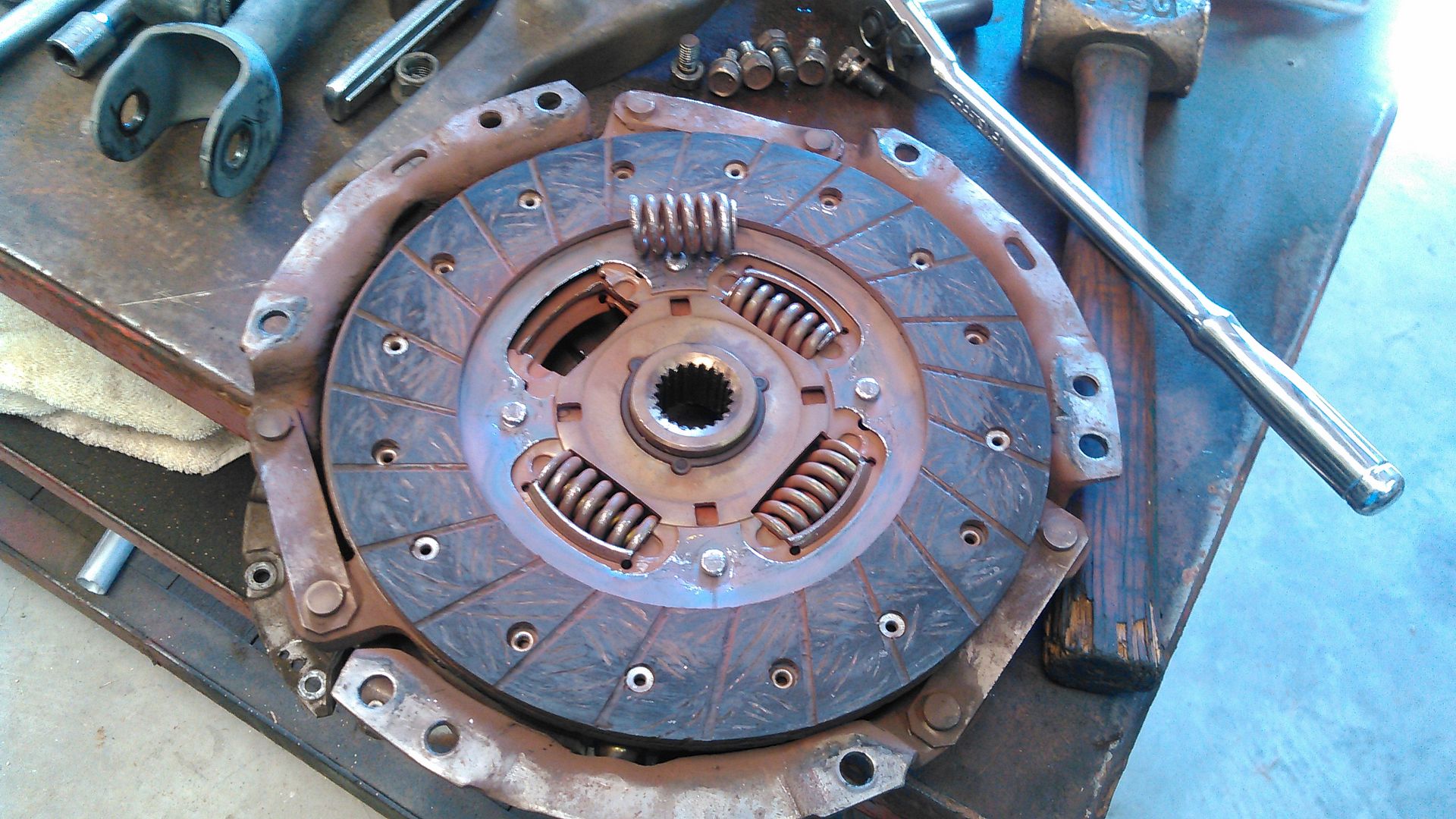

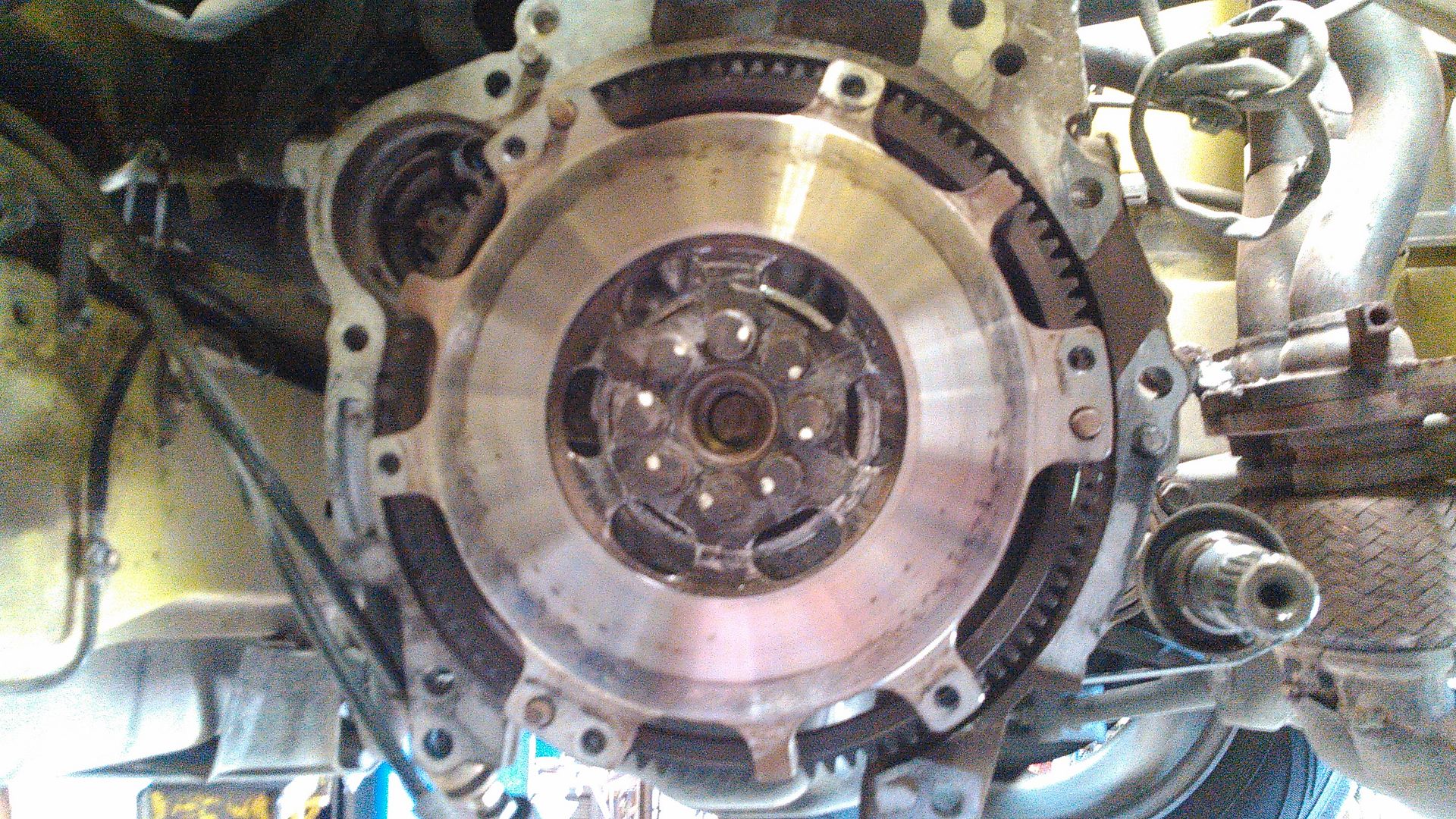

Here is the Clutch Disk..

The Spring Retainer broke, and let the Spring Come out.. There are actually TWO springs in there.. small one in the Inside of the Larger..

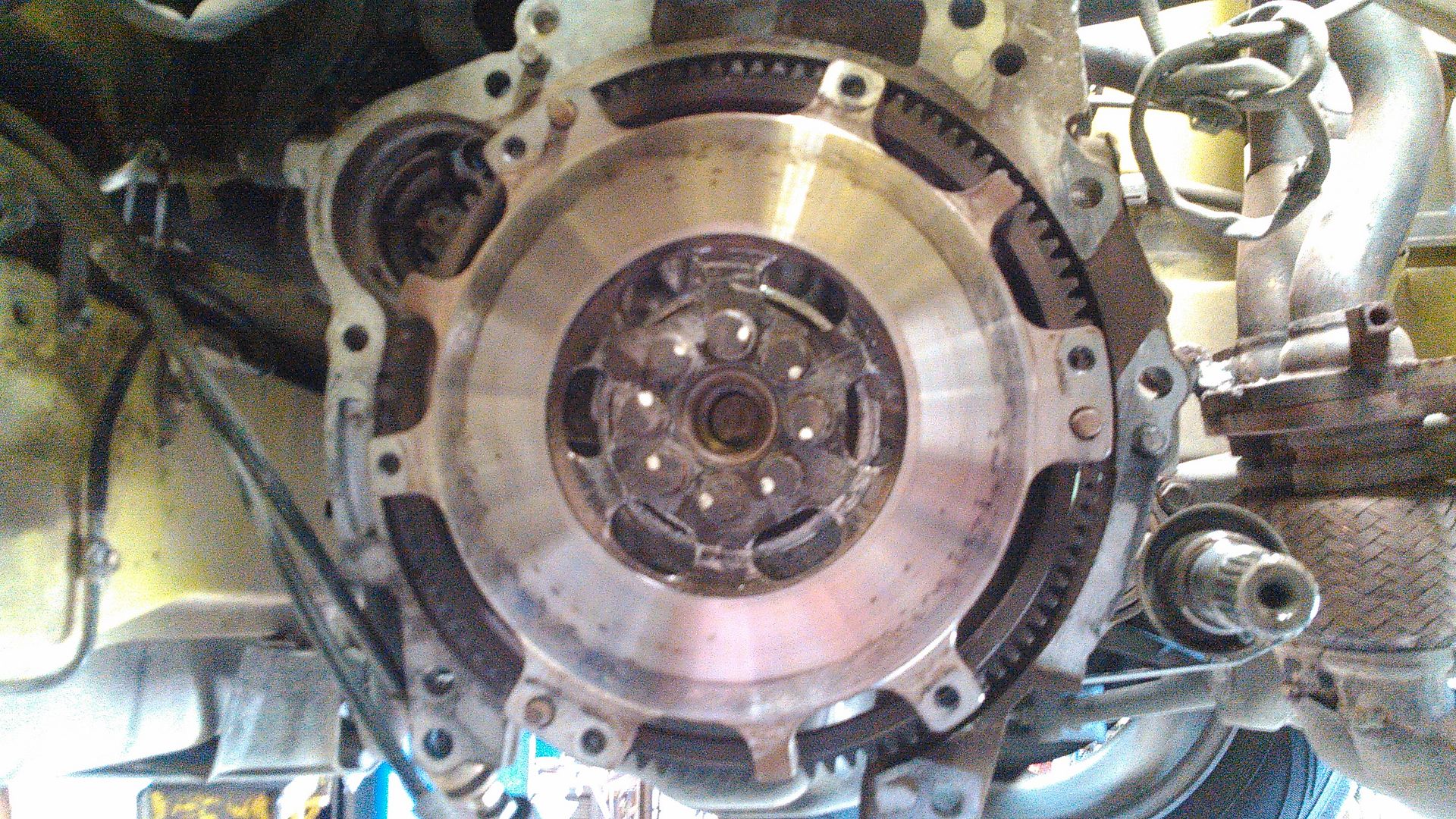

Now for the Flywheel...

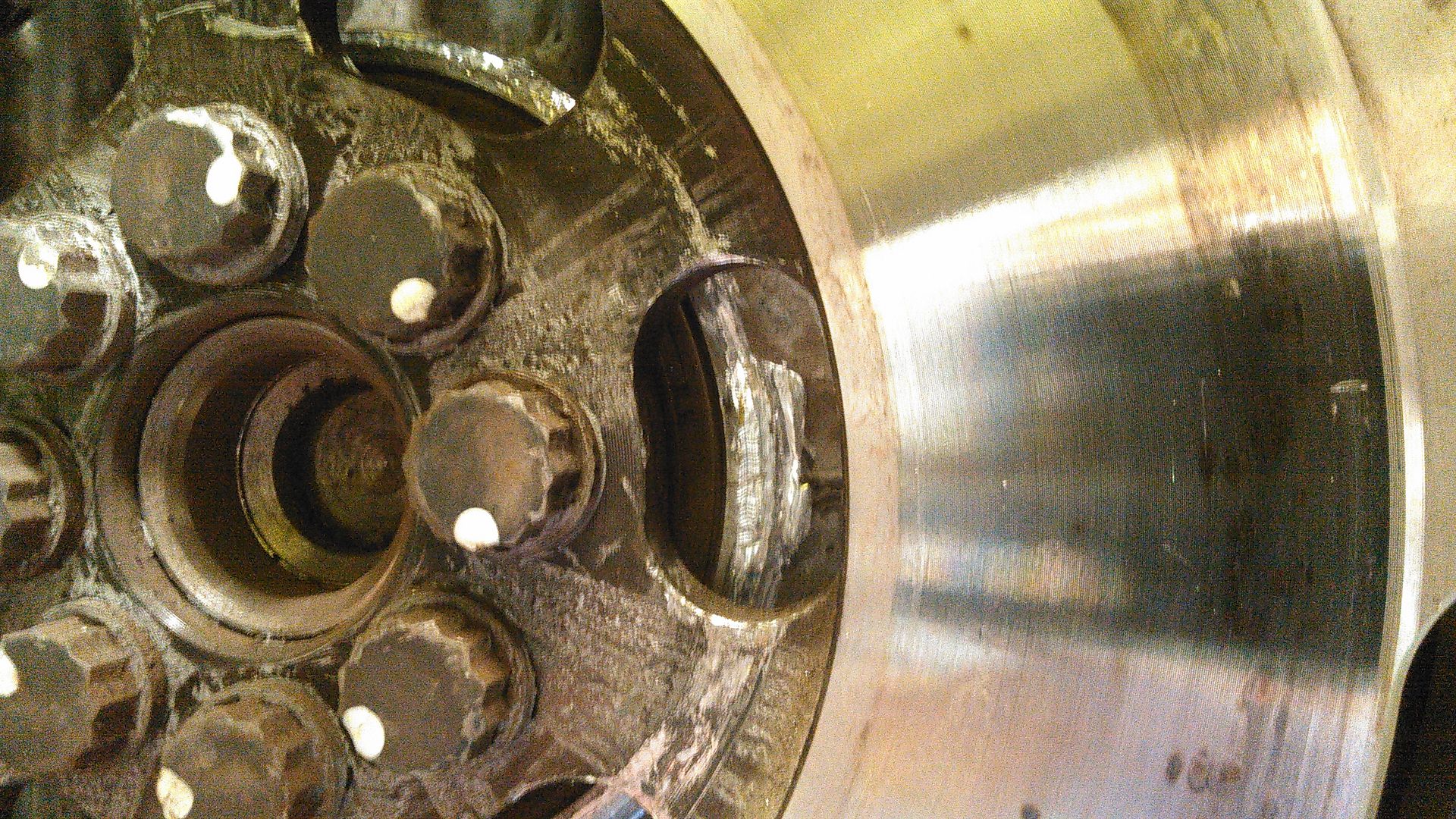

As you can see.. the Flywheel has 'Spokes' that hook the Center Section to the Friction Disk Surface..

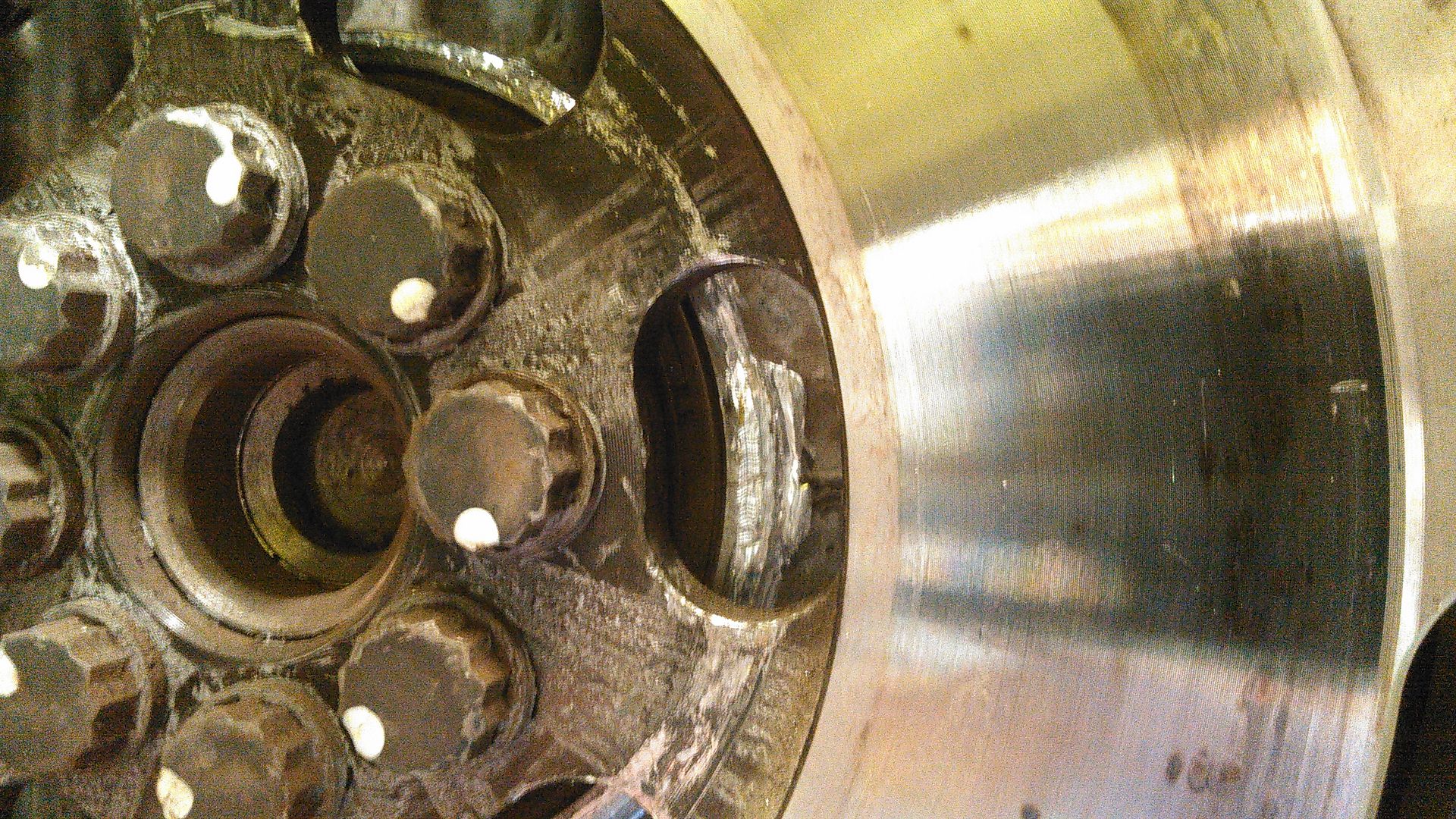

If you look 'Behind' the Spokes.. you will see where the Small Spring went through the Spoke, and started 'Chewing' the Block..

Nothing fatal happened to this Motor.. this Time..

BUT..

This was not a Failure I ever expected that could have been Fatal to the Block..

Had this been an Aluminum Flywheel, with the Removable Friction Surface, the Spring NEVER could have gotten through to the Block to cause Damage..

I still like the 'Feeling of Comfort' of having a Steel Flywheel, but I'm wonder if anyone that has Mucho Dollars invested in a Motor, might want to choose an Aluminum Flywheel to prevent this as a possible failure scenario for a motor..

Cap

When I decided to rebuild, I wanted a little more Zip.. I already had the MAF Mod ( Serial number 1! ).. and the next things to add were Cams and a Lightweight Flywheel..

The Cams were Crower Stage 1, and the Flywheel I purchased as New in Box from a Spyder member who decided to go 2ZZ ( Thanks Triz! )..

The Flywheel was a Light Weight Steel.. just what I wanted.. As aluminum kinda gives me the Kreeps..

I have about 40 K on this Flywheel.. and the Clutch had 120K when it went BACK in as used.. all checked out good.. my last Clutch had 175K miles and still looked good when I decided to take it out, I'd figure I toss this clutch back in.. with the new flywheel and Cams.. ( with the fresh rebuild of the Engine and trans..)

Last week on my way to work ( 175 Mile round trip ) my Clutch went from Fine to Fubar in one shift.. Lots of Noise, and would not disengage. I got to finish my drive to work, then back home again with out a clutch.. ( Must shift well or it's over )

I got the Clutch out today, and learned something..

Here is the Clutch Disk..

The Spring Retainer broke, and let the Spring Come out.. There are actually TWO springs in there.. small one in the Inside of the Larger..

Now for the Flywheel...

As you can see.. the Flywheel has 'Spokes' that hook the Center Section to the Friction Disk Surface..

If you look 'Behind' the Spokes.. you will see where the Small Spring went through the Spoke, and started 'Chewing' the Block..

Nothing fatal happened to this Motor.. this Time..

BUT..

This was not a Failure I ever expected that could have been Fatal to the Block..

Had this been an Aluminum Flywheel, with the Removable Friction Surface, the Spring NEVER could have gotten through to the Block to cause Damage..

I still like the 'Feeling of Comfort' of having a Steel Flywheel, but I'm wonder if anyone that has Mucho Dollars invested in a Motor, might want to choose an Aluminum Flywheel to prevent this as a possible failure scenario for a motor..

Cap